tarting a manufacturing business can transform your innovative product idea into a thriving enterprise. Whether you’re an entrepreneur with a revolutionary concept or an established business looking to bring production in-house, understanding the manufacturing startup process is crucial for success. Las Vegas, with its growing industrial sector and strategic location, offers exceptional opportunities for manufacturing ventures across industries from gaming equipment to renewable energy components.

Why Las Vegas is the Ideal Manufacturing Hub

Las Vegas manufacturing has evolved far beyond its entertainment roots. Southern Nevada’s manufacturing sector now supports critical industries including hospitality infrastructure, gaming equipment manufacturing, renewable energy projects, and aerospace components. The region’s strategic advantages include excellent transportation networks, competitive utility costs, business-friendly regulations, and access to skilled local machinists and operators with decades of precision manufacturing experience.

Step 1: Develop and Validate Your Product Idea

Concept Development

Start with a clear vision of what you want to manufacture. Consider whether you’re creating a completely new product or improving an existing one. Your product concept should address a specific market need and offer distinct advantages over current solutions.

Market Research and Validation

Thoroughly research your target market to understand demand, competition, and pricing expectations. Conduct surveys, focus groups, and competitive analysis to validate that your product concept has genuine market potential. Understanding your market early prevents costly mistakes later in the manufacturing process.

Niche Identification

Identify your specific niche within the manufacturing landscape. Las Vegas manufacturing specializes in diverse sectors including:

- Gaming and entertainment equipment

- Hospitality industry components

- Renewable energy systems

- Architectural metalwork

- Custom industrial equipment

Patent Research and Intellectual Property Protection

If your product is unique, conduct comprehensive patent research to ensure you’re not infringing on existing patents. Consider filing for your own patents or trademarks to protect your intellectual property before moving into production.

Prototyping Phase

Create functional prototypes to test your product’s design, functionality, and manufacturability. Prototyping helps identify design flaws early and allows you to refine your concept before committing to full production. Work with experienced fabricators who can provide input on design optimization for manufacturing efficiency.

Step 2: Develop a Comprehensive Business Plan

Essential Business Plan Components

Your manufacturing business plan should include:

- Executive summary with clear value proposition

- Detailed market analysis and competitive landscape

- Product specifications and manufacturing requirements

- Marketing and sales strategy

- Financial projections and funding requirements

- Operational plans and production schedules

- Risk assessment and mitigation strategies

Financial Planning and Projections

Determine your startup costs including equipment, facility setup, initial inventory, and working capital requirements. Develop realistic financial projections for the first 3-5 years, including projected revenues, costs of goods sold (COGS), operating expenses, and break-even analysis.

Funding Strategy Development

Manufacturing businesses typically require significant upfront investment. Explore funding options including:

- Personal savings and bootstrapping

- Small Business Administration (SBA) loans

- Traditional bank loans

- Angel investors and venture capital

- Crowdfunding platforms

- Equipment financing options

Step 3: Establish Your Manufacturing Operations

Location and Facility Selection

Choose a manufacturing location that supports your operational needs. Consider factors including:

- Proximity to suppliers and customers

- Access to skilled workforce

- Transportation and logistics infrastructure

- Utility availability and costs

- Zoning compliance and permits

- Room for future expansion

Las Vegas manufacturing benefits from excellent logistics infrastructure, with easy access to major highways, rail networks, and McCarran International Airport for shipping finished products nationwide.

Equipment and Technology Requirements

Identify and acquire the necessary manufacturing equipment based on your production requirements. Consider:

- Production volume requirements

- Quality standards and precision needs

- Material handling capabilities

- Safety and compliance requirements

- Maintenance and support availability

- Future scalability needs

Supplier Relationships and Supply Chain

Establish reliable relationships with suppliers for raw materials and components. Develop a robust supply chain that ensures consistent material availability while maintaining cost efficiency. Consider local suppliers when possible to reduce transportation costs and lead times.

Staffing and Workforce Development

Manufacturing requires skilled personnel including operators, technicians, quality control inspectors, and supervisors. Plan your initial staffing needs and consider Nevada’s pool of experienced manufacturing professionals, including many veteran-owned operations with proven expertise in precision manufacturing.

Step 4: Navigate Compliance and Quality Standards

Regulatory Compliance

Ensure compliance with all applicable regulations including:

- Local business licensing and permits

- Environmental regulations

- Worker safety (OSHA) requirements

- Industry-specific standards

- Quality certifications (ISO, etc.)

Quality Control Systems

Implement comprehensive quality control measures from day one. Establish standard operating procedures, inspection protocols, and continuous improvement processes to ensure consistent product quality that meets or exceeds customer expectations.

Safety Protocols

Develop and implement robust safety protocols to protect your workforce and comply with regulatory requirements. Regular safety training and proper equipment maintenance are essential for successful manufacturing operations.

Step 5: Marketing and Sales Strategy

Brand Development

Create a strong brand identity that communicates your value proposition and quality standards. Develop professional packaging and marketing materials that differentiate your products in the marketplace.

Sales Channel Strategy

Determine how you’ll sell your products:

- Direct-to-consumer sales

- Wholesale to retailers

- Online marketplaces

- Industrial/B2B sales channels

- Distribution partnerships

Digital Marketing for Manufacturing

Establish a professional online presence with a well-designed website optimized for search engines. Utilize digital marketing strategies including content marketing, social media, and targeted advertising to reach your ideal customers.

Step 6: Production Launch and Continuous Improvement

Pilot Production Runs

Start with small production runs to test your manufacturing processes, identify bottlenecks, and refine your operations before scaling to full production volumes.

Process Optimization

Continuously evaluate and optimize your manufacturing processes for efficiency, quality, and cost-effectiveness. Implement lean manufacturing principles to minimize waste and maximize productivity.

Customer Feedback Integration

Actively gather and respond to customer feedback to improve your products and processes. This ongoing dialogue helps ensure your manufacturing efforts align with market demands and expectations.

The StainlessMania Advantage: Your Las Vegas Manufacturing Partner

Successfully launching a manufacturing business requires more than just a great idea—it demands access to experienced manufacturing partners who understand the complexities of production. StainlessMania, Southern Nevada’s premier veteran-owned metal fabrication facility, offers the comprehensive manufacturing capabilities that startup businesses need to bring their products to market successfully.

World-Class Manufacturing Capabilities

StainlessMania’s Las Vegas manufacturing facility provides the advanced capabilities that modern product developers require:

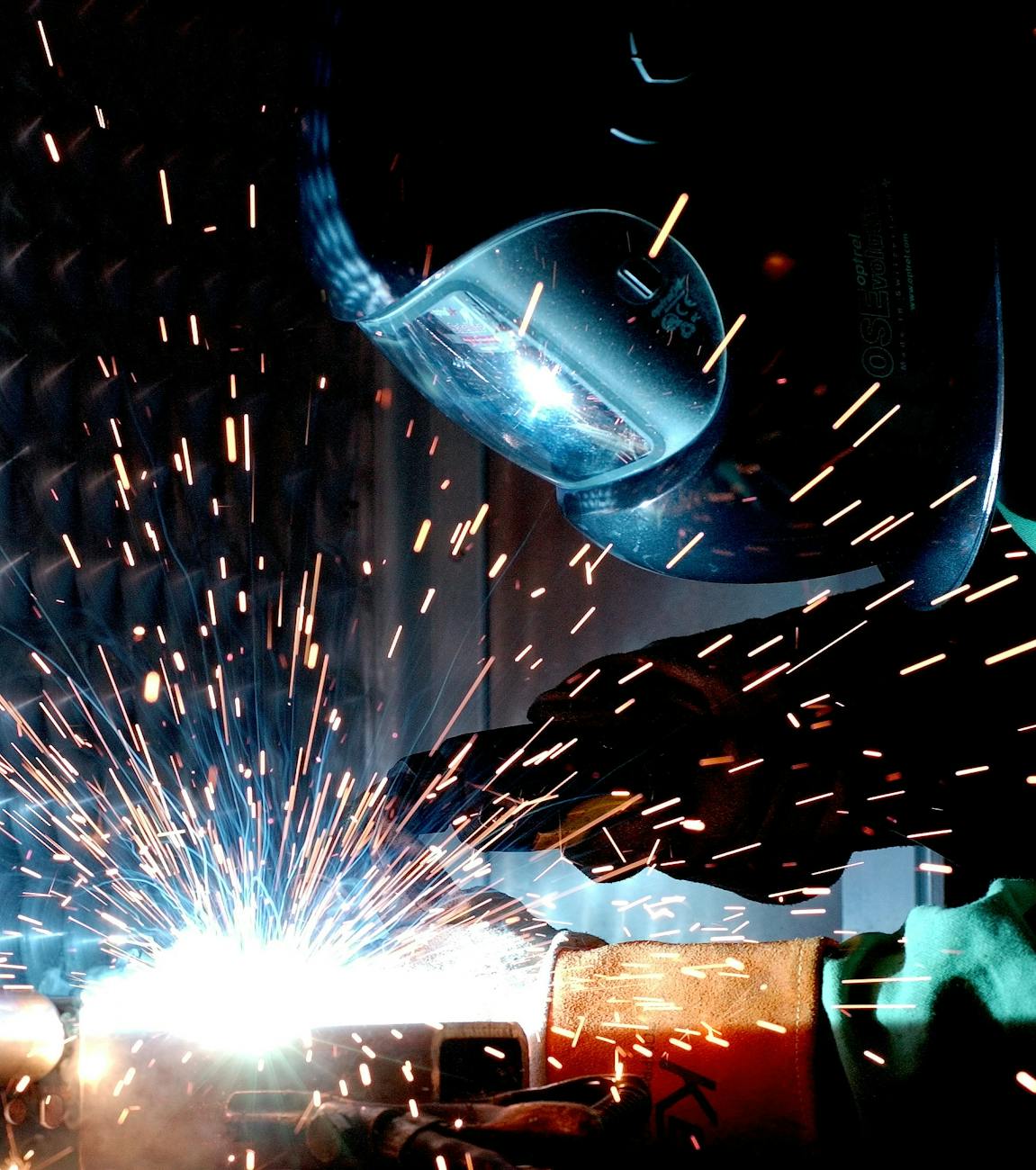

Precision Metal Fabrication Services:

- Advanced laser cutting for intricate designs and precise tolerances

- Expert metal bending and forming for complex geometries

- Professional MIG, TIG, and laser welding for superior joint quality

- State-of-the-art CNC routing and mill turn capabilities for exact specifications

Comprehensive Finishing Services:

- Professional assembly services for multi-component products

- Precision sanding for smooth, consistent surfaces

- Tumbling services for uniform surface textures and burr removal

Versatile Material Expertise:

- Stainless steel fabrication for corrosion resistance and aesthetic appeal

- Aluminum precision work for lightweight, durable components

- Mild steel processing for cost-effective structural applications

- HDPE fabrication for chemical resistance and specialized applications

The Value of Local Partnership

Working with local machinists and operators provides distinct advantages for manufacturing startups:

Rapid Prototyping and Iteration: Local partnership enables quick turnaround times for prototype development and design modifications, accelerating your time-to-market.

Cost-Effective Production: Eliminate shipping costs and logistics complications by working with a local manufacturing partner who understands Southern Nevada’s business environment.

Quality Collaboration: Direct communication with experienced fabricators ensures your design intent is properly translated into manufactured components.

Scalable Solutions: From prototype development through production runs, StainlessMania’s capabilities grow with your business needs.

Industry Experience That Matters

With decades of precision manufacturing experience serving Las Vegas’s diverse industrial sector, StainlessMania understands the unique challenges facing manufacturing startups. Our veteran-owned operation has successfully supported clients across multiple industries including:

- Gaming equipment manufacturing requiring precise tolerances and reliable performance

- Hospitality infrastructure projects demanding aesthetic appeal and durability

- Renewable energy components requiring corrosion resistance and long-term reliability

- Custom architectural elements for Las Vegas’s iconic skyline

Beyond Manufacturing: Complete Support

StainlessMania’s commitment to manufacturing excellence extends beyond traditional fabrication services. We provide:

Design Consultation: Our experienced team can provide input on design optimization for manufacturability, helping reduce costs and improve quality.

Value-Added Services: Vinyl application and 3D printing capabilities complement our metal fabrication services for complete product solutions.

Quality Assurance: Rigorous quality control processes ensure every component meets your specifications and performance requirements.

Your Path to Manufacturing Success Starts Here

Starting a manufacturing business requires careful planning, significant investment, and most importantly, the right manufacturing partners. While the steps outlined above provide the roadmap for success, having an experienced, local manufacturing partner can make the difference between struggling through the startup phase and achieving rapid, profitable growth.

StainlessMania’s combination of advanced manufacturing capabilities, experienced local operators, and veteran-owned reliability makes us the ideal partner for businesses ready to transform their product ideas into market-ready manufactured goods. Our Las Vegas manufacturing facility is equipped to handle everything from initial prototyping through full production runs, providing the flexibility and expertise that growing businesses need.

Whether you’re developing gaming equipment, hospitality infrastructure, renewable energy components, or custom architectural elements, StainlessMania has the capabilities, experience, and commitment to quality that your manufacturing startup demands.

Ready to start your manufacturing journey? Contact StainlessMania today to discuss how our comprehensive metal fabrication capabilities can bring your product vision to life. Our team of experienced local machinists and operators is ready to become your trusted manufacturing partner in Southern Nevada’s thriving industrial sector.

Start Your Project with StainlessMania—where precision manufacturing meets Southern Nevada reliability.